Böhler K110

Böhler K110 is a high-carbon tool steel characterized by high wear resistance and good dimensional stability after heat treatment.

K110 steel has been withdrawn from our stock offering.

As an alternative, we offer 1.2379 steel (EN ISO X153CrMoV12).

Inquiries regarding full production sheets of K110 steel only are handled on an individual basis — we encourage you to contact us via the contact form.

|

Thickness [mm]

|

Width [mm]

|

Length [mm]

|

Price without tax

|

Tax

|

Price

|

Available

|

Order quantity

|

|

|

|

|

|

|

|

|

|

||||

| 17.18 zł | 23 % | 21.13 zł | 0 | ||||||

| 20.21 zł | 23 % | 24.86 zł | 0 | ||||||

| 23.24 zł | 23 % | 28.59 zł | 0 | ||||||

| 27.28 zł | 23 % | 33.56 zł | 0 | ||||||

| 33.35 zł | 23 % | 41.02 zł | 0 | ||||||

| 22.24 zł | 23 % | 27.35 zł | 0 | ||||||

| 26.28 zł | 23 % | 32.32 zł | 0 | ||||||

| 31.33 zł | 23 % | 38.53 zł | 0 | ||||||

| 35.37 zł | 23 % | 43.51 zł | 0 | ||||||

| 44.46 zł | 23 % | 54.69 zł | 0 | ||||||

| 27.28 zł | 23 % | 33.56 zł | 0 | ||||||

| 33.35 zł | 23 % | 41.02 zł | 0 | ||||||

| 38.41 zł | 23 % | 47.24 zł | 0 | ||||||

| 43.46 zł | 23 % | 53.45 zł | 0 | ||||||

| 54.57 zł | 23 % | 67.12 zł | 0 | ||||||

| 32.34 zł | 23 % | 39.78 zł | 0 | ||||||

| 39.41 zł | 23 % | 48.48 zł | 0 | ||||||

| 45.48 zł | 23 % | 55.94 zł | 0 | ||||||

| 52.55 zł | 23 % | 64.64 zł | 0 | ||||||

| 64.67 zł | 23 % | 79.55 zł | 0 | ||||||

| 38.41 zł | 23 % | 47.24 zł | 0 | ||||||

| 45.48 zł | 23 % | 55.94 zł | 0 | ||||||

| 53.56 zł | 23 % | 65.88 zł | 0 | ||||||

| 60.63 zł | 23 % | 74.58 zł | 0 | ||||||

| 75.80 zł | 23 % | 93.23 zł | 0 | ||||||

| 43.46 zł | 23 % | 53.45 zł | 0 | ||||||

| 51.54 zł | 23 % | 63.39 zł | 0 | ||||||

| 60.63 zł | 23 % | 74.58 zł | 0 | ||||||

| 68.72 zł | 23 % | 84.53 zł | 0 | ||||||

| 85.90 zł | 23 % | 105.66 zł | 0 | ||||||

| 50.53 zł | 23 % | 62.15 zł | 0 | ||||||

| 60.63 zł | 23 % | 74.58 zł | 0 | ||||||

| 70.74 zł | 23 % | 87.01 zł | 0 | ||||||

| 80.85 zł | 23 % | 99.44 zł | 0 | ||||||

| 101.06 zł | 23 % | 124.30 zł | 0 | ||||||

| 60.63 zł | 23 % | 74.58 zł | 0 | ||||||

| 70.74 zł | 23 % | 87.01 zł | 0 | ||||||

| 80.85 zł | 23 % | 99.44 zł | 0 | ||||||

| 90.95 zł | 23 % | 111.87 zł | 0 | ||||||

| 111.16 zł | 23 % | 136.73 zł | 0 | ||||||

| 70.74 zł | 23 % | 87.01 zł | 0 | ||||||

| 80.85 zł | 23 % | 99.44 zł | 0 | ||||||

| 101.06 zł | 23 % | 124.30 zł | 0 | ||||||

| 111.16 zł | 23 % | 136.73 zł | 0 | ||||||

| 141.49 zł | 23 % | 174.03 zł | 0 | ||||||

| 80.85 zł | 23 % | 99.44 zł | 0 | ||||||

| 101.06 zł | 23 % | 124.30 zł | 0 | ||||||

| 111.16 zł | 23 % | 136.73 zł | 0 | ||||||

| 131.37 zł | 23 % | 161.59 zł | 0 | ||||||

| 161.70 zł | 23 % | 198.89 zł | 0 | ||||||

| 111.16 zł | 23 % | 136.73 zł | 0 | ||||||

| 131.37 zł | 23 % | 161.59 zł | 0 | ||||||

| 151.59 zł | 23 % | 186.46 zł | 0 | ||||||

| 171.80 zł | 23 % | 211.32 zł | 0 | ||||||

| 212.23 zł | 23 % | 261.04 zł | 0 | ||||||

| 481.30 zł | 23 % | 592.00 zł | 0 | ||||||

| 20.16 zł | 23 % | 24.80 zł | 0 | ||||||

| 24.20 zł | 23 % | 29.76 zł | 0 | ||||||

| 28.23 zł | 23 % | 34.72 zł | 0 | ||||||

| 32.25 zł | 23 % | 39.67 zł | 0 | ||||||

| 39.31 zł | 23 % | 48.35 zł | 0 | ||||||

| 26.21 zł | 23 % | 32.24 zł | 0 | ||||||

| 31.25 zł | 23 % | 38.44 zł | 0 | ||||||

| 36.28 zł | 23 % | 44.63 zł | 0 | ||||||

| 42.33 zł | 23 % | 52.07 zł | 0 | ||||||

| 52.41 zł | 23 % | 64.47 zł | 0 | ||||||

| 32.25 zł | 23 % | 39.67 zł | 0 | ||||||

| 39.31 zł | 23 % | 48.35 zł | 0 | ||||||

| 45.36 zł | 23 % | 55.79 zł | 0 | ||||||

| 51.41 zł | 23 % | 63.23 zł | 0 | ||||||

| 64.51 zł | 23 % | 79.35 zł | 0 | ||||||

| 39.31 zł | 23 % | 48.35 zł | 0 | ||||||

| 46.37 zł | 23 % | 57.03 zł | 0 | ||||||

| 54.43 zł | 23 % | 66.95 zł | 0 | ||||||

| 61.49 zł | 23 % | 75.63 zł | 0 | ||||||

| 77.62 zł | 23 % | 95.47 zł | 0 | ||||||

| 45.36 zł | 23 % | 55.79 zł | 0 | ||||||

| 54.43 zł | 23 % | 66.95 zł | 0 | ||||||

| 62.50 zł | 23 % | 76.87 zł | 0 | ||||||

| 71.57 zł | 23 % | 88.03 zł | 0 | ||||||

| 89.72 zł | 23 % | 110.35 zł | 0 | ||||||

| 51.41 zł | 23 % | 63.23 zł | 0 | ||||||

| 61.49 zł | 23 % | 75.63 zł | 0 | ||||||

| 71.57 zł | 23 % | 88.03 zł | 0 | ||||||

| 81.65 zł | 23 % | 100.43 zł | 0 | ||||||

| 101.80 zł | 23 % | 125.22 zł | 0 | ||||||

| 60.48 zł | 23 % | 74.39 zł | 0 | ||||||

| 70.56 zł | 23 % | 86.79 zł | 0 | ||||||

| 80.64 zł | 23 % | 99.19 zł | 0 | ||||||

| 90.72 zł | 23 % | 111.59 zł | 0 | ||||||

| 120.96 zł | 23 % | 148.78 zł | 0 | ||||||

| 70.56 zł | 23 % | 86.79 zł | 0 | ||||||

| 80.64 zł | 23 % | 99.19 zł | 0 | ||||||

| 90.72 zł | 23 % | 111.59 zł | 0 | ||||||

| 100.80 zł | 23 % | 123.98 zł | 0 | ||||||

| 131.04 zł | 23 % | 161.18 zł | 0 | ||||||

| 80.64 zł | 23 % | 99.19 zł | 0 | ||||||

| 100.80 zł | 23 % | 123.98 zł | 0 | ||||||

| 110.88 zł | 23 % | 136.38 zł | 0 | ||||||

| 131.04 zł | 23 % | 161.18 zł | 0 | ||||||

| 161.28 zł | 23 % | 198.37 zł | 0 | ||||||

| 100.80 zł | 23 % | 123.98 zł | 0 | ||||||

| 120.96 zł | 23 % | 148.78 zł | 0 | ||||||

| 141.12 zł | 23 % | 173.58 zł | 0 | ||||||

| 151.20 zł | 23 % | 185.98 zł | 0 | ||||||

| 191.52 zł | 23 % | 235.57 zł | 0 | ||||||

| 131.04 zł | 23 % | 161.18 zł | 0 | ||||||

| 151.20 zł | 23 % | 185.98 zł | 0 | ||||||

| 181.44 zł | 23 % | 223.17 zł | 0 | ||||||

| 201.60 zł | 23 % | 247.97 zł | 0 | ||||||

| 252.00 zł | 23 % | 309.96 zł | 0 | ||||||

| 570.73 zł | 23 % | 702.00 zł | 0 | ||||||

| 23.19 zł | 23 % | 28.52 zł | 0 | ||||||

| 27.22 zł | 23 % | 33.48 zł | 0 | ||||||

| 32.25 zł | 23 % | 39.67 zł | 0 | ||||||

| 36.28 zł | 23 % | 44.63 zł | 0 | ||||||

| 45.36 zł | 23 % | 55.79 zł | 0 | ||||||

| 30.24 zł | 23 % | 37.20 zł | 0 | ||||||

| 36.28 zł | 23 % | 44.63 zł | 0 | ||||||

| 42.33 zł | 23 % | 52.07 zł | 0 | ||||||

| 47.37 zł | 23 % | 58.27 zł | 0 | ||||||

| 59.47 zł | 23 % | 73.15 zł | 0 | ||||||

| 37.29 zł | 23 % | 45.87 zł | 0 | ||||||

| 44.35 zł | 23 % | 54.55 zł | 0 | ||||||

| 51.41 zł | 23 % | 63.23 zł | 0 | ||||||

| 59.47 zł | 23 % | 73.15 zł | 0 | ||||||

| 73.59 zł | 23 % | 90.51 zł | 0 | ||||||

| 44.35 zł | 23 % | 54.55 zł | 0 | ||||||

| 53.42 zł | 23 % | 65.71 zł | 0 | ||||||

| 61.49 zł | 23 % | 75.63 zł | 0 | ||||||

| 70.56 zł | 23 % | 86.79 zł | 0 | ||||||

| 87.70 zł | 23 % | 107.87 zł | 0 | ||||||

| 51.41 zł | 23 % | 63.23 zł | 0 | ||||||

| 61.49 zł | 23 % | 75.63 zł | 0 | ||||||

| 71.57 zł | 23 % | 88.03 zł | 0 | ||||||

| 81.65 zł | 23 % | 100.43 zł | 0 | ||||||

| 102.81 zł | 23 % | 126.46 zł | 0 | ||||||

| 58.46 zł | 23 % | 71.91 zł | 0 | ||||||

| 70.56 zł | 23 % | 86.79 zł | 0 | ||||||

| 81.65 zł | 23 % | 100.43 zł | 0 | ||||||

| 93.75 zł | 23 % | 115.31 zł | 0 | ||||||

| 116.93 zł | 23 % | 143.82 zł | 0 | ||||||

| 70.56 zł | 23 % | 86.79 zł | 0 | ||||||

| 80.64 zł | 23 % | 99.19 zł | 0 | ||||||

| 90.72 zł | 23 % | 111.59 zł | 0 | ||||||

| 110.88 zł | 23 % | 136.38 zł | 0 | ||||||

| 131.04 zł | 23 % | 161.18 zł | 0 | ||||||

| 80.64 zł | 23 % | 99.19 zł | 0 | ||||||

| 90.72 zł | 23 % | 111.59 zł | 0 | ||||||

| 100.80 zł | 23 % | 123.98 zł | 0 | ||||||

| 120.96 zł | 23 % | 148.78 zł | 0 | ||||||

| 151.20 zł | 23 % | 185.98 zł | 0 | ||||||

| 90.72 zł | 23 % | 111.59 zł | 0 | ||||||

| 110.88 zł | 23 % | 136.38 zł | 0 | ||||||

| 131.04 zł | 23 % | 161.18 zł | 0 | ||||||

| 151.20 zł | 23 % | 185.98 zł | 0 | ||||||

| 181.44 zł | 23 % | 223.17 zł | 0 | ||||||

| 110.88 zł | 23 % | 136.38 zł | 0 | ||||||

| 131.04 zł | 23 % | 161.18 zł | 0 | ||||||

| 151.20 zł | 23 % | 185.98 zł | 0 | ||||||

| 181.44 zł | 23 % | 223.17 zł | 0 | ||||||

| 221.76 zł | 23 % | 272.76 zł | 0 | ||||||

| 151.20 zł | 23 % | 185.98 zł | 0 | ||||||

| 181.44 zł | 23 % | 223.17 zł | 0 | ||||||

| 201.60 zł | 23 % | 247.97 zł | 0 | ||||||

| 231.84 zł | 23 % | 285.16 zł | 0 | ||||||

| 292.32 zł | 23 % | 359.55 zł | 0 | ||||||

| 643.90 zł | 23 % | 792.00 zł | 0 |

OUR STEEL IS FOR YOU, IF:

| You value precisely cut material We cut steel using band saws, ensuring straight edges. We do not use guillotine shears, which can warp sheets and round their edges. |

|

| Minor scratches or residue are not an issue for you Sometimes, a single steel sheet passes through the saw multiple times, which may cause slight surface scratches. Occasionally, delicate spot traces of surface corrosion (thin residue) may appear on the steel due to coolant remnants from the cutting process. Both scratches and residue can be easily removed during grinding. If you require steel with a perfectly clean surface, our product will not meet your expectations. |

|

| You can straighten minor surface deviations yourself We strive to deliver perfectly flat steel pieces, but we cannot guarantee 100% flatness. Any slight surface curvature is not a material defect but rather a result of mill tolerances (flatness tolerances for rolled products). An experienced knifemaker can handle such a curvature in no time. |

|

| You want to buy steel from trusted supplier We source our steel from the largest manufacturers in Europe and beyond. Each delivery is precisely marked with an industrial hand jet printer to prevent errors during cutting and storage. |

|

| You don't like overpaying Our mission is to provide you with a piece of steel that is as close as possible to the shape of the knife you want to make. With us, you don't have to buy a large piece of steel and make unnecessary supplies or throw unnecessary surpluses in the trash. |

Example photo of a steel sheet:

K110 – High Hardness and Wear Resistance in Knifemaking

Böhler K110 steel is a tool steel known for its exceptional wear resistance and durability. Widely used in knifemaking, it is the European equivalent of the American D2 steel and is highly regarded by knifemakers worldwide. Below are presented the chemical composition, heat treatment, achieved hardness, and a comparison of K110 steel with other steels used in knifemaking.

Chemical Composition of K110 Steel – What Makes It Stand Out?

| Element |

Composition |

| Carbon (C) | 1,55% |

| Manganese (Mn) |

0,30% |

| Silicon (Si) | 0,30% |

| Chromium (Cr) | 11,3% |

| Molybdenum (Mo) | 0,75% |

| Vanadium (V) | 0,75% |

K110 is a high-carbon, high-chromium tool steel that delivers strength and wear resistance. Its chemical composition plays a critical role in achieving optimal performance in knives.

- Carbon (C): 1.55% – Enhances hardness and hardenability.

- Chromium (Cr): 11.3% – High chromium content improves corrosion resistance and wear resistance.

- Molybdenum (Mo): 0.75% – Boosts hardenability and wear resistance.

- Vanadium (V): 0.75% – Improves toughness and cutting edge stability.

This combination of elements sets K110 apart from other tool steels, offering properties that make it ideal for crafting utility and outdoor knives.

Heat Treatment of K110 Steel

Heat treatment difficulty shown at the top of this page reflects the most common choice in our survey of Polish knifemakers, prepared with input from an experienced heat treater. Please treat it as community guidance, not a specification.

“EASY-TO-HARDEN” denotes a more forgiving steel — one that delivers predictable, useful results even with minor deviations in process parameters.

“DIFFICULT-TO-HARDEN” calls for tight process control; small mistakes can quickly degrade the final outcome.

LEGAL NOTICE REGARDING HEAT TREATMENT

Heat treatment is a set of processes dependent on many variables, including knife thickness, the type of furnace and process atmosphere, soaking time and temperature, the method and temperature of cooling, as well as tempering parameters.

The data presented below are provided for informational purposes only and do not constitute technical advice, a technological instruction, or any assurance of achieving specific properties or results. IK STAL is not liable for any consequences arising from the use of this data without prior verification and adaptation to the user’s individual technological conditions. For detailed guidance, we recommend consulting experienced heat treaters. The above provisions do not limit the statutory rights of consumers.

Hardening of K110 Steel

Austenitizing

The austenitizing process for K110 steel involves heating to 1030-1070°C (1886-1958°F) and holding at the set temperature for 15-30 minutes, counting from the moment the steel reaches a uniform temperature. The times given by the manufacturer refer to industrial components; the times for thin parts are not specified.

Practical austenitizing guidelines:

- The thicker the blade, the longer it should stay in the furnace.

- Keeping the steel in the furnace too long can lead to grain growth; too short a time leads to incomplete austenitizing (incomplete microstructural transformation). Put simply: at the correct temperature, leaving the steel in the furnace a little longer usually does less harm than taking it out too early. The biggest mistake is using an incorrect austenitizing temperature.

Quenching

Quenching media: oil, air, salt bath at 220-250°C or 500-550°C (428-482°F or 932-1022 °F).

Sub-zero Treatment (Optional)

In the available sources there are no clear contraindications to using sub-zero (cryogenic) treatment for K110 steel. In practice, part of the knifemaking community applies it to potentially achieve an increase in hardness of around +1-2 HRC and improved dimensional stability. It should be emphasized, however, that the manufacturer neither describes nor recommends this step in the official specification, therefore the decision to use cryogenic treatment should result solely from the user’s own experience and informed choice.

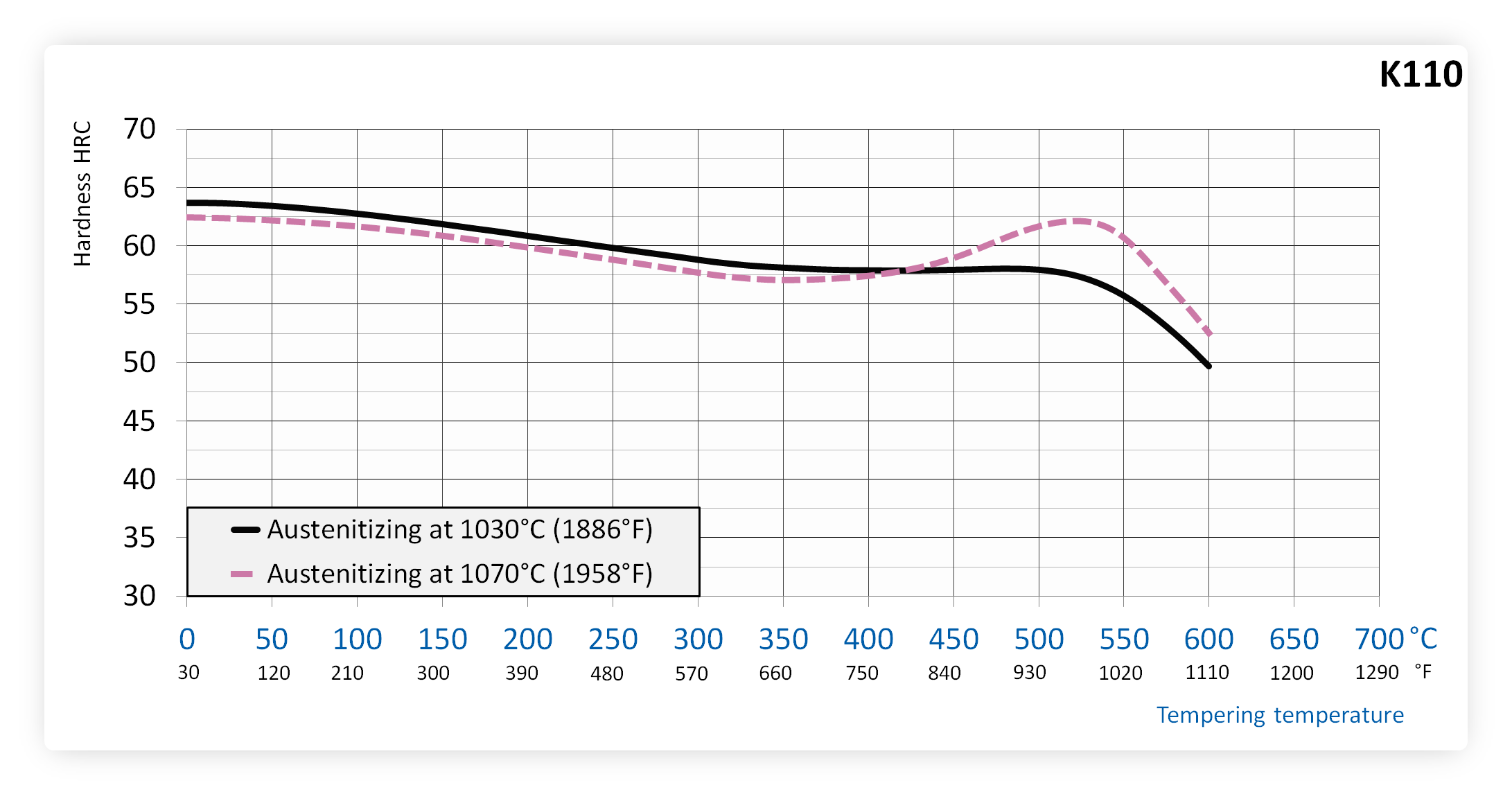

Tempering of K110 Steel

Tempering is the controlled reheating of a hardened blade to a chosen temperature and holding it for a set time to reduce brittleness and stresses from hardening and increase the knife’s impact toughness.

Böhler recommends tempering the steel at 515-560°C (959-1040°F) after prior quenching from an austenitizing temperature of 1070 °C (1958 °F).

Temper for 1 hour per each 20 mm of material thickness, but at least 2 hours. In industrial practice, a minimum of two full tempering cycles is recommended.

Additional stress relieving after tempering

Böhler states in the technical datasheet for K110 steel that additional stress relieving after tempering (for example after finish machining in the hardened condition) can be carried out. It should be performed at a temperature 30-50°C (86-122°F) below the highest tempering temperature previously applied in order to minimize the loss of hardness.

K110 Steel Tempering Chart

Comparison of K110 Steel with Other Steels in Knifemaking

K110 is often compared with other tool and knife steels, such as N690 and Elmax. Here's how it fares against these popular materials.

K110 vs. N690

N690 offers better corrosion resistance than K110, which is crucial for knives used in humid environments. However, K110 surpasses N690 in wear resistance, making it ideal for tools subjected to heavy-duty use.

K110 vs. Elmax

Elmax steel provides excellent corrosion resistance and higher toughness than K110. However, K110 is a more cost-effective choice and offers higher hardness, making it suitable for outdoor and survival knives.

Applications of K110 Steel in Knives

Due to its properties, K110 steel is well-suited for various types of knives. Here are the knives where it performs best:

Hunting Knives

K110 is ideal for hunting knives that require long-lasting sharpness and durability. Its wear resistance makes it suitable for heavy-duty use during hunting trips. However, proper maintenance of the knife must be remembered, as K110 steel is not stainless steel.

Outdoor and Survival Knives

Thanks to its high hardness and wear resistance, K110 excels in outdoor and survival knives exposed to harsh conditions. These knives can handle tasks such as cutting wood or preparing shelters.

Utility Knives

K110 is also popular for utility knives that must be reliable and durable. Its properties make it suitable for everyday use and tasks requiring precision and strength.

How to Maintain Knives Made of K110 Steel?

Although K110 offers better corrosion resistance than many other tool steels, proper maintenance is essential:

- Cleaning – After each use, clean and dry the knife thoroughly to minimize corrosion risk.

- Oiling – Regular application of protective oil helps maintain the blade’s condition.

- Sharpening – Use diamond or ceramic stones to sharpen K110, ensuring a perfect edge.

Conclusion – Why Choose K110 Steel?

K110 steel is an exceptional material for knifemakers and knife users who value durability, hardness, and wear resistance. Its structure and properties make it ideal for hunting, outdoor, and utility knives, offering long blade life and high quality.

K110 steel is classified as semi-stainless, meaning it has some corrosion resistance due to its high chromium content. However, it is not fully rust-proof and requires regular maintenance.

When properly heat-treated, K110 steel can achieve a hardness of 58-62 HRC, ensuring excellent durability and the ability to maintain a sharp cutting edge.

K110 steel is ideal for hunting, outdoor, and utility knives. Its wear resistance makes it perfect for tools that require high durability and sharpness.

Due to its high hardness, K110 requires precise sharpening techniques. Diamond or ceramic stones are recommended to achieve and maintain the desired sharpness efficiently.

The key difference lies in corrosion resistance—N690 is more rust-resistant, making it a better choice for humid conditions. On the other hand, K110 offers superior wear resistance and higher hardness, making it ideal for heavy-duty applications.