1.2067 (102Cr6 / ~NC4 / ~52100)

Steel 1.2067 (102Cr6, equivalent to AISI 52100) is a high-carbon tool steel offering high hardness and excellent wear resistance.

|

Thickness [mm]

|

Width [mm]

|

Length [mm]

|

Price without tax

|

Tax

|

Price

|

Available

|

Order quantity

|

|

|

|

|

|

|

|

|

|

||||

| 7.34 zł | 23 % | 9.03 zł | 40 | ||||||

| 9.03 zł | 23 % | 11.11 zł | 21 | ||||||

| 10.72 zł | 23 % | 13.19 zł | 18 | ||||||

| 11.85 zł | 23 % | 14.58 zł | 16 | ||||||

| 14.67 zł | 23 % | 18.05 zł | 13 | ||||||

| 10.16 zł | 23 % | 12.50 zł | 19 | ||||||

| 11.85 zł | 23 % | 14.58 zł | 16 | ||||||

| 13.54 zł | 23 % | 16.66 zł | 14 | ||||||

| 15.80 zł | 23 % | 19.44 zł | 12 | ||||||

| 19.76 zł | 23 % | 24.30 zł | 9 | ||||||

| 12.41 zł | 23 % | 15.27 zł | 15 | ||||||

| 14.67 zł | 23 % | 18.05 zł | 13 | ||||||

| 16.93 zł | 23 % | 20.83 zł | 11 | ||||||

| 19.20 zł | 23 % | 23.61 zł | 10 | ||||||

| 24.28 zł | 23 % | 29.86 zł | 8 | ||||||

| 14.67 zł | 23 % | 18.05 zł | 13 | ||||||

| 17.50 zł | 23 % | 21.52 zł | 11 | ||||||

| 20.33 zł | 23 % | 25.00 zł | 9 | ||||||

| 23.15 zł | 23 % | 28.47 zł | 8 | ||||||

| 28.79 zł | 23 % | 35.41 zł | 6 | ||||||

| 16.93 zł | 23 % | 20.83 zł | 11 | ||||||

| 20.33 zł | 23 % | 25.00 zł | 9 | ||||||

| 23.71 zł | 23 % | 29.16 zł | 8 | ||||||

| 27.10 zł | 23 % | 33.33 zł | 7 | ||||||

| 33.30 zł | 23 % | 40.96 zł | 5 | ||||||

| 19.20 zł | 23 % | 23.61 zł | 10 | ||||||

| 23.15 zł | 23 % | 28.47 zł | 8 | ||||||

| 27.10 zł | 23 % | 33.33 zł | 7 | ||||||

| 30.48 zł | 23 % | 37.49 zł | 6 | ||||||

| 38.38 zł | 23 % | 47.21 zł | 5 | ||||||

| 22.58 zł | 23 % | 27.77 zł | 8 | ||||||

| 28.23 zł | 23 % | 34.72 zł | 6 | ||||||

| 33.87 zł | 23 % | 41.66 zł | 5 | ||||||

| 33.87 zł | 23 % | 41.66 zł | 5 | ||||||

| 45.15 zł | 23 % | 55.54 zł | 4 | ||||||

| 28.23 zł | 23 % | 34.72 zł | 6 | ||||||

| 28.23 zł | 23 % | 34.72 zł | 6 | ||||||

| 33.87 zł | 23 % | 41.66 zł | 5 | ||||||

| 39.51 zł | 23 % | 48.60 zł | 4 | ||||||

| 50.80 zł | 23 % | 62.49 zł | 3 | ||||||

| 33.87 zł | 23 % | 41.66 zł | 5 | ||||||

| 39.51 zł | 23 % | 48.60 zł | 4 | ||||||

| 45.15 zł | 23 % | 55.54 zł | 4 | ||||||

| 50.80 zł | 23 % | 62.49 zł | 3 | ||||||

| 62.09 zł | 23 % | 76.37 zł | 3 | ||||||

| 39.51 zł | 23 % | 48.60 zł | 4 | ||||||

| 45.15 zł | 23 % | 55.54 zł | 4 | ||||||

| 50.80 zł | 23 % | 62.49 zł | 3 | ||||||

| 56.45 zł | 23 % | 69.43 zł | 3 | ||||||

| 73.38 zł | 23 % | 90.26 zł | 2 | ||||||

| 50.80 zł | 23 % | 62.49 zł | 3 | ||||||

| 56.45 zł | 23 % | 69.43 zł | 3 | ||||||

| 67.74 zł | 23 % | 83.32 zł | 2 | ||||||

| 79.02 zł | 23 % | 97.20 zł | 2 | ||||||

| 95.96 zł | 23 % | 118.03 zł | 2 | ||||||

| 7.07 zł | 23 % | 8.70 zł | 174 | ||||||

| 8.33 zł | 23 % | 10.24 zł | 148 | ||||||

| 9.58 zł | 23 % | 11.78 zł | 129 | ||||||

| 10.82 zł | 23 % | 13.31 zł | 114 | ||||||

| 13.74 zł | 23 % | 16.90 zł | 90 | ||||||

| 9.15 zł | 23 % | 11.26 zł | 135 | ||||||

| 10.82 zł | 23 % | 13.31 zł | 114 | ||||||

| 12.49 zł | 23 % | 15.36 zł | 99 | ||||||

| 14.15 zł | 23 % | 17.41 zł | 87 | ||||||

| 17.90 zł | 23 % | 22.02 zł | 69 | ||||||

| 11.24 zł | 23 % | 13.82 zł | 110 | ||||||

| 13.32 zł | 23 % | 16.38 zł | 92 | ||||||

| 15.40 zł | 23 % | 18.94 zł | 80 | ||||||

| 17.90 zł | 23 % | 22.02 zł | 69 | ||||||

| 22.07 zł | 23 % | 27.14 zł | 56 | ||||||

| 13.32 zł | 23 % | 16.38 zł | 92 | ||||||

| 15.82 zł | 23 % | 19.46 zł | 78 | ||||||

| 18.32 zł | 23 % | 22.53 zł | 67 | ||||||

| 21.23 zł | 23 % | 26.11 zł | 58 | ||||||

| 26.23 zł | 23 % | 32.26 zł | 47 | ||||||

| 15.40 zł | 23 % | 18.94 zł | 80 | ||||||

| 18.32 zł | 23 % | 22.53 zł | 67 | ||||||

| 21.64 zł | 23 % | 26.62 zł | 57 | ||||||

| 24.56 zł | 23 % | 30.21 zł | 50 | ||||||

| 30.39 zł | 23 % | 37.38 zł | 40 | ||||||

| 17.48 zł | 23 % | 21.50 zł | 70 | ||||||

| 20.81 zł | 23 % | 25.60 zł | 59 | ||||||

| 24.56 zł | 23 % | 30.21 zł | 0 | ||||||

| 27.89 zł | 23 % | 34.30 zł | 44 | ||||||

| 34.97 zł | 23 % | 43.01 zł | 35 | ||||||

| 20.81 zł | 23 % | 25.60 zł | 59 | ||||||

| 24.98 zł | 23 % | 30.72 zł | 49 | ||||||

| 29.14 zł | 23 % | 35.84 zł | 42 | ||||||

| 33.30 zł | 23 % | 40.96 zł | 37 | ||||||

| 41.63 zł | 23 % | 51.20 zł | 29 | ||||||

| 24.98 zł | 23 % | 30.72 zł | 49 | ||||||

| 29.14 zł | 23 % | 35.84 zł | 42 | ||||||

| 33.30 zł | 23 % | 40.96 zł | 37 | ||||||

| 37.46 zł | 23 % | 46.08 zł | 33 | ||||||

| 45.79 zł | 23 % | 56.32 zł | 27 | ||||||

| 29.14 zł | 23 % | 35.84 zł | 42 | ||||||

| 33.30 zł | 23 % | 40.96 zł | 37 | ||||||

| 37.46 zł | 23 % | 46.08 zł | 33 | ||||||

| 45.79 zł | 23 % | 56.32 zł | 27 | ||||||

| 54.11 zł | 23 % | 66.56 zł | 22 | ||||||

| 33.30 zł | 23 % | 40.96 zł | 37 | ||||||

| 41.63 zł | 23 % | 51.20 zł | 29 | ||||||

| 45.79 zł | 23 % | 56.32 zł | 27 | ||||||

| 54.11 zł | 23 % | 66.56 zł | 22 | ||||||

| 66.60 zł | 23 % | 81.92 zł | 18 | ||||||

| 45.79 zł | 23 % | 56.32 zł | 27 | ||||||

| 54.11 zł | 23 % | 66.56 zł | 22 | ||||||

| 62.44 zł | 23 % | 76.80 zł | 19 | ||||||

| 70.76 zł | 23 % | 87.04 zł | 17 | ||||||

| 87.41 zł | 23 % | 107.52 zł | 14 |

OUR STEEL IS FOR YOU, IF:

| You value precisely cut material We cut steel using band saws, ensuring straight edges. We do not use guillotine shears, which can warp sheets and round their edges. |

|

| Minor scratches or residue are not an issue for you Sometimes, a single steel sheet passes through the saw multiple times, which may cause slight surface scratches. Occasionally, delicate spot traces of surface corrosion (thin residue) may appear on the steel due to coolant remnants from the cutting process. Both scratches and residue can be easily removed during grinding. If you require steel with a perfectly clean surface, our product will not meet your expectations. |

|

| You can straighten minor surface deviations yourself We strive to deliver perfectly flat steel pieces, but we cannot guarantee 100% flatness. Any slight surface curvature is not a material defect but rather a result of mill tolerances (flatness tolerances for rolled products). An experienced knifemaker can handle such a curvature in no time. |

|

| You want to buy steel from trusted supplier We source our steel from the largest manufacturers in Europe and beyond. Each delivery is precisely marked with an industrial hand jet printer to prevent errors during cutting and storage. |

|

| You don't like overpaying Our mission is to provide you with a piece of steel that is as close as possible to the shape of the knife you want to make. With us, you don't have to buy a large piece of steel and make unnecessary supplies or throw unnecessary surpluses in the trash. |

Example photo of a steel sheet:

Basic parameters:

- Thickness tolerance: 0/+0,2 mm (the surface is not precision ground)

- Cutting tolerance: we cut the steel on band saws to a tolerance of 0/+3 mm (width x length)

- Delivery conditon: steel in non-hardened condition (steel requires hardening)

Steel 1.2067 (102Cr6 / ~AISI 52100) in Knifemaking – Properties and Applications

The steel we offer is 1.2067, also known as 102Cr6 (similar in its parameters to steel steel AISI 52100) , is a high-carbon tool steel with a high chromium content. It is widely recognized for its exceptional hardness, wear resistance, and excellent edge retention, making it a preferred material for knifemaking and other precision tools. Below are presented information on the properties, advantages, heat treatment processes, and applications of 1.2067 steel.

Why Is Steel 1.2067 (102Cr6 / ~AISI 52100) Popular in Knifemaking?

Steel 1.2067 has gained popularity among knifemakers due to its unique combination of properties:

- High Hardness – After heat treatment, this steel achieves hardness levels of up to 60-62 HRC, ensuring outstanding cutting edge retention.

- Wear Resistance – Its high carbon and chromium content make it highly resistant to wear and abrasion, ideal for knives subjected to intense use.

- Dimensional Stability – Provides excellent stability during machining and heat treatment, ensuring consistent performance in high-precision applications.

Chemical Composition of Steel 1.2067 (102Cr6)

| Element |

Composition |

| Carbon (C) | 1,00% |

| Manganese (Mn) |

0,30% |

| Silicon (Si) | 0,25% |

| Chromium (Cr) | 1,50% |

Steel 1.2067 features a chemical composition tailored for durability and performance:

- Carbon (C): 1% – Enhances hardness and edge retention.

- Chromium (Cr): 1.5% – Increases wear resistance and provides moderate corrosion resistance.

- Manganese (Mn): 0.3% – Improves strength and hardenability.

- Silicon (Si): 0.25% – Adds toughness and strength.

This composition gives steel 1.2067 an optimal balance of hardness, wear resistance, and machinability.

Heat Treatment of Steel 1.2067 (102Cr6)

Heat treatment difficulty shown at the top of this page reflects the most common choice in our survey of Polish knifemakers, prepared with input from an experienced heat treater. Please treat it as community guidance, not a specification.

“EASY-TO-HARDEN” denotes a more forgiving steel — one that delivers predictable, useful results even with minor deviations in process parameters.

“DIFFICULT-TO-HARDEN” calls for tight process control; small mistakes can quickly degrade the final outcome.

LEGAL NOTICE REGARDING HEAT TREATMENT

Heat treatment is a set of processes dependent on many variables, including knife thickness, the type of furnace and process atmosphere, soaking time and temperature, the method and temperature of cooling, as well as tempering parameters.

The data presented below are provided for informational purposes only and do not constitute technical advice, a technological instruction, or any assurance of achieving specific properties or results. IK STAL is not liable for any consequences arising from the use of this data without prior verification and adaptation to the user’s individual technological conditions. For detailed guidance, we recommend consulting experienced heat treaters. The above provisions do not limit the statutory rights of consumers.

Hardening of Steel 1.2067 (102Cr6)

Austenitizing

The austenitizing process for 1.2067 steel involves heating to 830–860°C (1525-1580°F) and holding at the set temperature for 15 minutes, counting from the moment the steel reaches a uniform temperature.

Practical austenitizing guidelines:

- The thicker the blade, the longer it should stay in the furnace.

- Keeping the steel in the furnace too long can lead to grain growth; too short a time leads to incomplete austenitizing (incomplete microstructural transformation). Put simply: at the correct temperature, leaving the steel in the furnace a little longer usually does less harm than taking it out too early. The biggest mistake is using an incorrect austenitizing temperature.

Quenching

After austenitizing, 1.2067 steel is cooled. Quenching media: oil.

Tempering of Steel 1.2067 (102Cr6)

Tempering is the controlled reheating of a hardened blade to a chosen temperature and holding it for a set time to reduce brittleness and stresses from hardening and increase the knife’s impact toughness.

When tempering, two cycles are most commonly used, typically 1-2 hours each. According to the opinion of practitioners, it is enough to temper steel once for 2 hours.

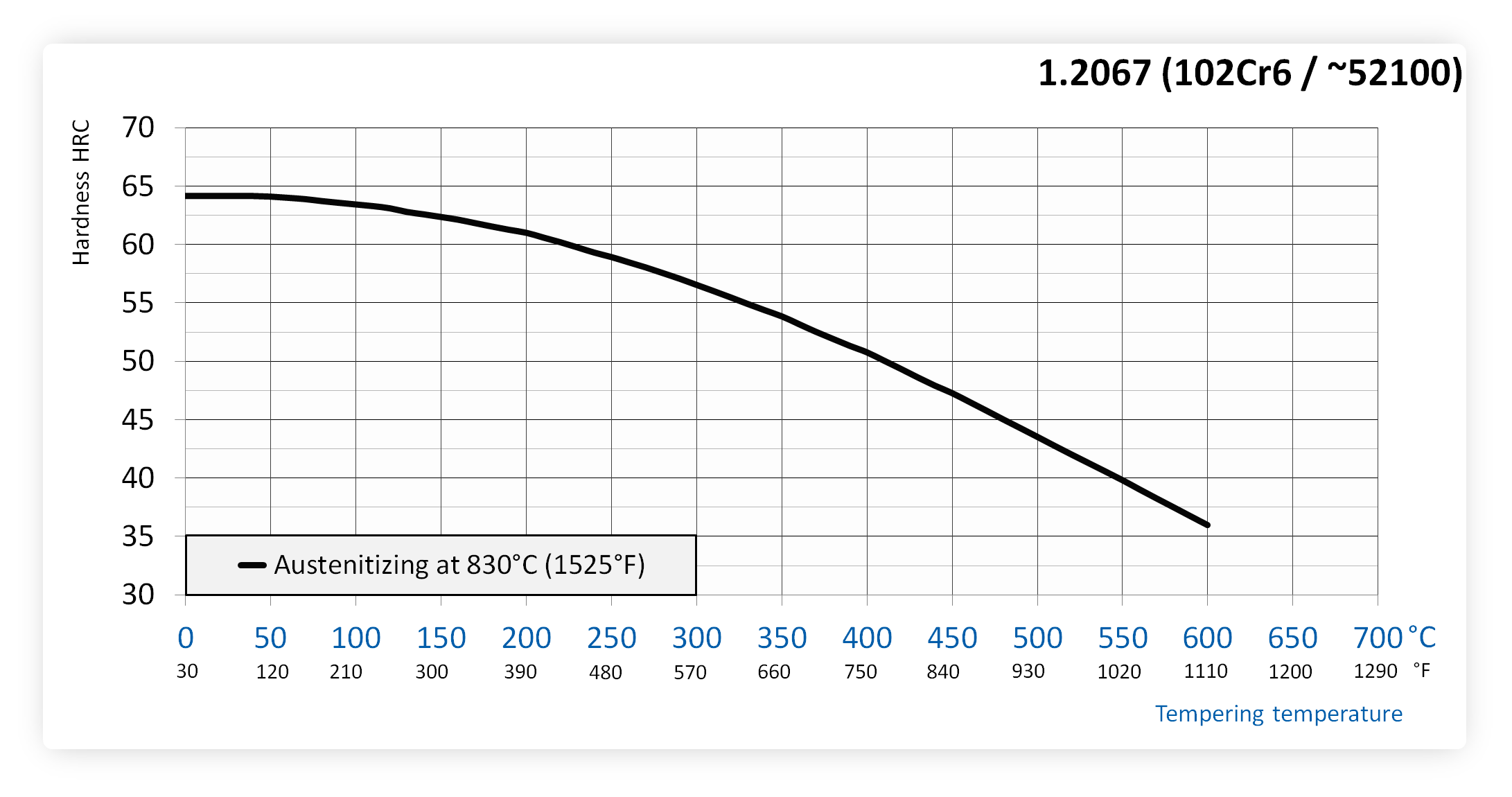

Steel 1.2067 (102Cr6) Tempering Chart

The chart is given for a hardened specimen measuring Ø30 mm x 40 mm (length):

Applications of Steel 1.2067 (102Cr6 / ~AISI 52100) in Knifemaking

Steel 1.2067 is highly versatile and widely used in various knife types:

Utility Knives

Steel 1.2067 offers outstanding edge retention and wear resistance, making it perfect for knives used in heavy-duty applications such as cutting hard materials.

Outdoor and Survival Knives

With its high hardness and resistance to abrasion, steel 1.2067 is an excellent choice for outdoor knives that need to endure harsh conditions.

Advantages of Steel 1.2067 (102Cr6 / ~AISI 52100) in Knifemaking

- Exceptional Edge Retention – Maintains sharpness over prolonged use, reducing the need for frequent sharpening.

- High Wear Resistance – Ensures durability even under intensive use.

- Customizable Properties – Heat treatment allows for fine-tuning of toughness and hardness based on specific knife requirements.

- Good Machinability – In the annealed state, steel 1.2067 is easy to machine, allowing for intricate designs and precision manufacturing.

Comparison of 1.2067 (102Cr6) steel with similar grades according to international standards (PN, EN, DIN, AISI, GOST and others)

| Country / Standard | Steel Designation | Remarks |

| Poland (PN) | ~NC4 or ~ŁH15 | PN equivalents; high-carbon, high-chromium bearing steel |

| Europe (EN 10132-4) | 102Cr6 | Official EN 10132-4 designation for cold-work tool steel |

| Germany (DIN) | 1.2067 / 102Cr6 | Classification per DIN EN 10132-4 |

| Austria (Böhler) | PV6 | Böhler trade name for a grade similar to 1.2067 |

| USA (AISI/ASTM) | AISI 52100 / ASTM A295 | AISI/ASTM equivalent; high-carbon, high-chromium bearing steel |

| UK (BS) | 534A99 / 535A99 | BS 970 equivalents |

| France (AFNOR) | 100C6 | AFNOR equivalent; high-carbon, high-chromium bearing steel |

| Italy (UNI) | 100Cr6 | Same as the German designation |

| Czech Republic (ČSN) | 14109 | ČSN equivalent; high-carbon, high-chromium bearing steel |

| Japan (JIS) | SUJ2 | JIS equivalent; high-carbon, high-chromium bearing steel |

| Russia (GOST) | ШХ15 (ShKh15) | GOST equivalent; high-carbon, high-chromium bearing steel |

Availability of Steel 1.2067 (102Cr6 / ~AISI 52100)

IK STAL stocks and supplies steel grade 1.2067 (102Cr6 / ~52100) in the form of flat bars, plates and cut-to-size blanks.

Material is available directly from our warehouse in Poland.

International Supply and Shipping

Steel

1.2067 (102Cr6 / ~52100) is supplied by IK STAL to customers across Europe,

including the United Kingdom and selected non-European markets.

Orders are shipped from Poland regardless of local steel standards, naming conventions or customs procedures.

Where to buy Steel 1.2067 (102Cr6 / ~AISI 52100)?

Steel grade 1.2067 (102Cr6 / ~52100) can be purchased directly from IK STAL.

We supply tool steel 1.2067 (102Cr6 / ~52100) to industrial and craft customers across

Europe and selected non-European markets, offering cut-to-size formats

without minimum order quantities.

Conclusion – Why Choose Steel 1.2067 (102Cr6)?

Steel 1.2067 is a high-performance material offering outstanding hardness, wear resistance, and edge retention, making it a preferred choice for knifemaking. Its adaptability through heat treatment ensures it meets the specific needs of various knife applications, from heavy-duty utility knives to precision cutting tools. With proper maintenance, knives made from 1.2067 steel deliver exceptional performance and longevity.

Its combination of high hardness, wear resistance, and edge retention makes it perfect for both utility and precision knives.

While it has moderate corrosion resistance due to its chromium content, it is not stainless steel and requires proper maintenance to prevent rust.

After hardening and tempering, it achieves a hardness level of 60–62 HRC, making it suitable for demanding applications.

Compared to similar steels, 1.2067 offers superior wear resistance and edge retention while maintaining good machinability.

Hardening at 830–860°C (1525-1580°F) with oil quenching, and tempering at 175–220°C (347–428°F) for desired properties.